Post Page

Key Criteria for Comparing and Selecting Building Stones

Comparing and Selecting Building Stones

Choosing the right building stone requires a multi-dimensional approach that considers technical, aesthetic, environmental, and economic factors.

The following framework presents a comprehensive guideline for evaluating and comparing natural stones used in architecture and construction.

Defining Application and Environmental Conditions

Before anything else, the final use and installation environment must be identified:

- Installation area: façade, indoor/outdoor flooring, stairs, lobby, pool, landscape, etc.

- Environmental conditions: temperature, humidity, wet–dry cycles, salinity, heavy traffic, and exposure to cleaning chemicals.

📌 Importance: This step determines which tests, standards, and acceptance limits are required for technical approval.

Physical & Mechanical Properties

Reliable laboratory test data form the foundation of all engineering decisions.

Key indicators include:

- Density & Water Absorption (ASTM C97): predict behavior under humidity and freeze–thaw cycles.

- Compressive Strength (ASTM C170): defines the stone’s ability to bear vertical loads.

- Flexural Strength & Modulus of Rupture (ASTM C880 / C99): measure bending resistance for slabs and load-bearing spans.

- Abrasion Resistance (ASTM C1353): critical for high-traffic flooring areas.

- Freeze–Thaw Durability (EN 12371): evaluates resistance to freezing and thawing damage.

💡 Execution note: Always request the raw test data from the supplier and verify the test date and validity.

Surface Safety & Slip Resistance

For both indoor and outdoor floors, slip resistance must comply with international standards:

- Europe: EN 16165 (replacing BS 7976).

- USA: ANSI A326.3.

Testing should cover dry, wet, and oily conditions according to actual usage.

Chemical & Salt Durability

- Resistance to acidic and alkaline cleaners.

- Resistance to salt exposure, pool chlorine, or seawater.

- Relevant tests: EN 12371 and water-absorption index.

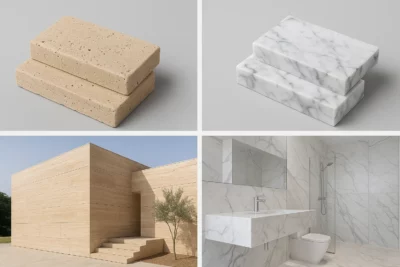

- Aesthetic & Geological Features

- Color and Uniformity: stability of tone across large installations.

- Texture and Structure: uniform or varied (cloudy, fossil, veined, or wavy).

- Patterns: ability to apply book-match or four-match designs.

- Finishes: Polished, Honed, Brushed, Flamed, Leathered, tumbled — each affects appearance, slip resistance, and maintenance.

- Anisotropy & Layering: directional properties affecting strength and durability.

- Compatibility with Installation Systems

- Dry cladding / anchorage systems: ASTM C1354 (Anchorage Test).

- Mortar or cement-bed installation: ASTM C482 (Bond Strength).

Stone selection must correspond with the chosen installation system and structural design.

Mock-Up & Quality Control (QC)

- Full-scale mock-up panels should be built to evaluate color, joints, book-match patterns, and finish.

- Final acceptance should be based on on-site QC and approved mock-ups.

Sustainability & Green Standards

- Environmental certifications: ANSI/NSC 373 or the updated ANSI/NSI 373-2019.

- Supporting documents: EPD (Environmental Product Declaration) and LCA (Life-Cycle Assessment) for carbon-footprint review.

Sustainability adds measurable value to both project and brand reputation.

Supply Continuity, Uniformity & Dimensions

- Quarry and factory production capacity.

- Color stability between consecutive shipments.

- Waste ratio and maximum block/slab/tile dimensions.

- Lead Time and transportation risks.

These operational factors can be as decisive as laboratory performance results.

Life-Cycle Cost (LCC)

Beyond the purchase price, include:

- Waterproofing and periodic maintenance costs.

- Cleaning and potential restoration costs.

- Long-term aesthetic durability.

Selecting the proper finish can significantly reduce long-term maintenance expenses.

Glossary of Technical Terms

- Application & Environment: intended use and surrounding conditions defining technical requirements.

- Density: mass per volume, indicating compactness and strength.

- Water Absorption (ASTM C97): percentage of water absorbed; key for freeze–thaw resistance.

- Compressive Strength (ASTM C170): load-bearing capacity under vertical pressure.

- Flexural Strength (ASTM C880 / C99): bending resistance for slabs and spans.

- Modulus of Rupture: maximum stress before fracture.

- Abrasion Resistance (ASTM C1353): surface wear resistance for heavy traffic.

- Freeze–Thaw Resistance (EN 12371): ability to withstand repeated freezing cycles.

- Slip Resistance: surface friction value against slipping.

- Pendulum Test (BS 7976 / EN 16165): European method measuring slip potential.

- ANSI A326.3: U.S. standard for hard-surface slip performance.

- Chemical Durability: resistance to acids, alkalis, and detergents.

- Salt Crystallization: salt-induced deterioration through pore crystallization.

- Veining: natural lines or patterns in the stone affecting both beauty and structure.

- Anisotropy: directional variation of mechanical properties.

- Finish: surface treatment (Polished, Honed, Brushed, Flamed, Leathered, Tumbled).

- Book Match: mirror placement of two slabs to form a symmetrical pattern.

- Four Match: arrangement of four slabs to create a unified four-way design.

- Dry Cladding: mechanical façade installation without mortar.

- Anchorage Test (ASTM C1354): measures stone anchoring strength in façade systems.

- Bond Strength (ASTM C482): evaluates adhesion to cement or mortar.

- Mock-Up: full-scale sample used for visual and quality approval.

- QC (Quality Control): process ensuring uniformity and compliance.

- EPD: verified environmental impact statement for a product.

- LCA: assessment of total environmental impact throughout life cycle.

- LCC: total cost over a product’s life, including maintenance and repair.

- Lead Time: duration from order to delivery, including extraction and shipping.

Frequently Asked Questions (FAQ)

Section 1 – Application & Environment

- Why is it necessary to define location and conditions before choosing a stone?

Because the installation area and environment determine which technical standards, tests, and acceptance limits are needed. For example, exterior façades or pool areas face humidity, salinity, and temperature cycles that demand different durability and slip-resistance levels than indoor walls. - Which stones are best suited for cold and freeze-prone regions?

Stones with low-water absorption and high freeze–thaw resistance (EN 12371) — such as dense granite, compact limestone, or quartzite — perform best in freezing climates. - Can an interior stone be used outdoors?

Not necessarily. Interior stones often lack freeze–thaw durability, UV resistance, or chemical stability required for outdoor exposure. Always verify the technical test data before exterior use.

Section 2 – Physical & Mechanical Properties

- Why are water absorption and density so important?

They indicate how the stone behaves under humidity and temperature changes.

- Low absorption + high density → better resistance to freeze–thaw damage, staining, and salt attack.

- High absorption → higher risk of cracking and weathering.

- What is the role of compressive strength in a project?

It measures the stone’s ability to bear vertical loads (ASTM C170). Essential for columns, base cladding, or any load-bearing application. - Where is flexural strength most critical?

In slabs, stairs, façades, and large-span panels that experience bending or wind pressure. Tests like ASTM C880 / C99 assess this property. - Why is abrasion resistance vital for high-traffic floors?

Because it measures how well the surface resists wear and scratching (ASTM C1353). High abrasion resistance ensures long-term durability in malls, lobbies, or public walkways. - How can the validity of test reports be confirmed?

By requesting the original lab data, verifying the test date, standard (ASTM/EN), and ensuring the tests are performed by accredited laboratories. Outdated or non-certified results are unreliable.

Section 3 – Slip Safety

- What does the Pendulum Test measure?

It measures the surface friction (slip potential) using a swinging pendulum under dry, wet, or oily conditions — showing how slippery a stone surface is. - What’s the difference between EN 16165 (EU) and ANSI A326.3 (US)?

Both measure slip resistance but use different testing procedures and classification systems:

- EN 16165 (Europe) replaced BS 7976.

- ANSI A326.3 (USA) defines Dynamic Coefficient of Friction (DCOF).

- Are polished surfaces always slippery?

Polished stones tend to have lower friction, especially when wet, but not all are unsafe. Slip resistance depends on finish type and environment — honed, brushed, or leathered surfaces often provide better traction.

Section 4 – Chemical & Salt Durability

- How do cleaning chemicals affect stone surfaces?

Acidic or alkaline cleaners can etch, dull, or discolor natural stones, especially marble and limestone. Proper chemical resistance testing is required. - Which stones perform best in pools or saline environments?

Stones with low porosity and high salt/chlorine resistance, like granite, basalt, or certain compact limestones tested under EN 12371, are ideal. - How does salt crystallization damage stone?

When saline water evaporates, salts crystallize inside pores, creating internal pressure that leads to flaking, scaling, or disintegration over time.

Section 5 – Aesthetic & Structural Aspects

- What is the difference between Book-Match and Four-Match patterns?

- Book-Match: two adjoining slabs are mirrored to form a symmetrical design.

- Four-Match: four slabs arranged to create a unified, four-way pattern — ideal for feature walls or floors.

- Do veins or fossils weaken a stone, or are they purely aesthetic?

They are mostly aesthetic but can affect structure if the veins are open, filled, or run directionally (anisotropy). Strong veining may reduce flexural strength. - Which finishes balance beauty and slip-resistance for heavy-use areas?

Honed, brushed, leathered, tumbled, or flamed finishes — they reduce gloss while maintaining natural texture and safe slip performance.

Section 6 – Installation & Quality Control

- What is the difference between mortar installation and dry anchorage systems?

- Mortar installation (ASTM C482): stones are bonded to substrate using cement or adhesive.

- Dry anchorage (ASTM C1354): mechanical fixing system (clips, anchors) used mainly for façades without mortar.

- Why must a mock-up be prepared before final installation?

To verify real appearance, joints, pattern alignment, and finish quality before mass production. It ensures client approval and reduces costly on-site errors. - How does quality control (QC) influence stone selection?

QC ensures color uniformity, dimensional accuracy, and defect-free finishing — verifying that delivered stone matches approved samples and technical requirements.

Section 7 – Sustainability & Environment

- What does the ANSI/NSC 373 standard cover?

It certifies sustainably quarried and processed natural stone, evaluating environmental, social, and health impacts — including water use, energy, and site management. - What information do EPD and LCA documents provide?

- EPD (Environmental Product Declaration): verified data on a product’s environmental impact.

- LCA (Life-Cycle Assessment): analyzes total impact from extraction to disposal (carbon footprint, energy, emissions).

- Why is carbon footprint an important selection factor?

Because it reflects a stone’s environmental responsibility — lower emissions improve sustainability scores and project reputation in green certifications (LEED, BREEAM).

Section 8 – Supply & Life-Cycle Cost

- Why is quarry and factory capacity important in stone selection?

It guarantees consistent supply, color uniformity, and large-scale availability — essential for projects requiring long-term or phased deliveries. - What does “Lead Time” mean, and how does it affect project scheduling?

Lead time = the total duration from order to delivery, including quarrying, cutting, finishing, and transport. Long lead times can delay project progress. - Why should Life Cycle Cost (LCC) be considered alongside the initial price?

Because the true cost includes maintenance, cleaning, and restoration over time — a cheaper stone may cost more long-term if it requires frequent repairs. - Which finish types help reduce long-term maintenance costs?

Honed, leathered, or brushed finishes — they hide scratches, resist stains better than polished surfaces, and reduce the need for periodic re-polishing.

Online Catalogue

Online Catalogue