From Our Own Quarries and Factories — A Wide Portfolio of Natural Stones Crafted for Global Architecture

- ISO 9001 • Exporting to 30+ Countries Worldwide

Production Excellence with

Worldwide Reach

Karimi Stone operates two modern stone processing facilities with 50,000 m² and 12,000 m² of covered production space, along with two active quarries. Equipped with advanced Italian machinery, our factories produce a complete range of natural stone products, including slabs, tiles, pavers, mosaics, bathtubs, washbasins, and other customized stone elements, all available in a wide variety of professional finishes.

This strong production capacity, combined with flexible payment terms, competitive pricing, and fast delivery schedules, has positioned Karimi Stone as one of the leading stone processing companies in Iran and among the country’s largest exporters of natural stone. Additional services such as international shipping, third-party inspections, and full export documentation further enhance our reliability and competitiveness across global markets.

Crafted by Heritage, Refined by Technology

karimi stone began its journey with the establishment of Derakhshan Factory and has grown, across three generations, into a reliable global source of premium natural stone. With more than fifty years of continuous experience, Karimi Stone is recognized as one of the most trusted names in Iran’s stone industry and a long-term partner for architectural and construction projects worldwide.

Today, karimi stone operates two modern stone factories equipped for high-volume and project-based production. Our facilities manufacture a wide range of natural stones according to exact project dimensions, finishes, and technical specifications. Every order is supported by a dedicated quality control team, ensuring consistent quality, precise tolerances, and dependable performance from production to delivery.

Karimi Stone has been present at major international stone exhibitions, including Marmomac in Italy, The Big 5 in Dubai, and leading stone events in Russia. These exhibitions have strengthened our long-term relationships with architects, developers, contractors, and distributors across global markets.

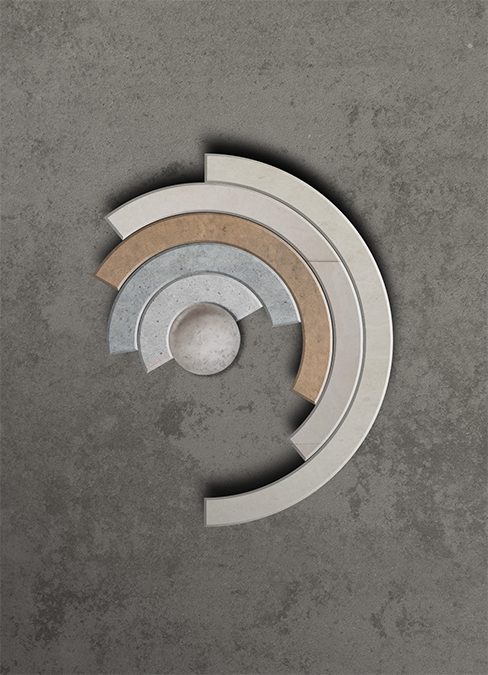

Our product portfolio at karimi stone includes travertine, marble, limestone, granite, and onyx in professional finishes such as polished, honed, brushed, bush-hammered, sandblasted, and tumbled. Production formats include slabs, tiles, steps, pavers, pattern sets, CNC-processed elements, and mosaics. Each production lot is fully traceable, photographed, and inspected at the source, with block quality, vein direction, and thickness carefully verified before packing.

Packaging at Karimi Stone is engineered specifically for long-distance export. We use steel-banded bundles, fumigated wooden crates, reinforced edge protection, and secure container lashing to ensure maximum safety and stability during international transportation.

Environmental responsibility is an integral part of karimi stone operations. Our production process includes water recycling systems, waste conversion into aggregates, and optimized logistics planning to reduce environmental impact while maintaining the craftsmanship, durability, and reliability expected from a world-class natural stone supplier.

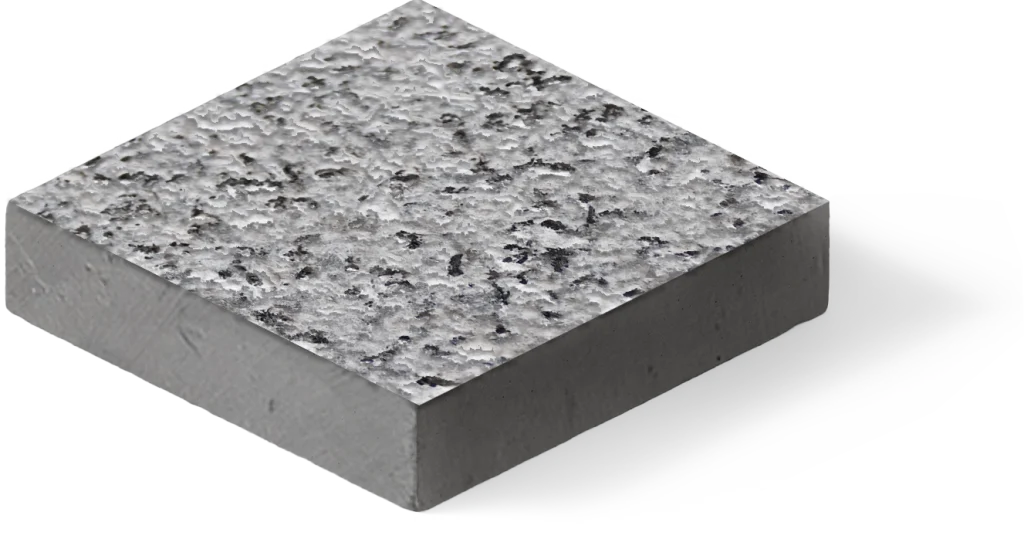

Sandblasting is a surface treatment widely used in architectural Stone Products to create non-slip textures and reduce the risk of slipping. At karimi stone, achieving a high-quality sandblasted finish starts with preparing the stone to a honed or semi-honed surface before sandblasting. This preparation ensures a clean, even, and controlled final texture.

Sandblasting can be carried out either manually or by machine; however, machine-based processing delivers far more uniform and consistent results. In professional Stone Products manufacturing at karimi stone, the process is performed by projecting silica grains or iron filings onto the stone surface under high pressure, creating a durable and evenly textured finish.

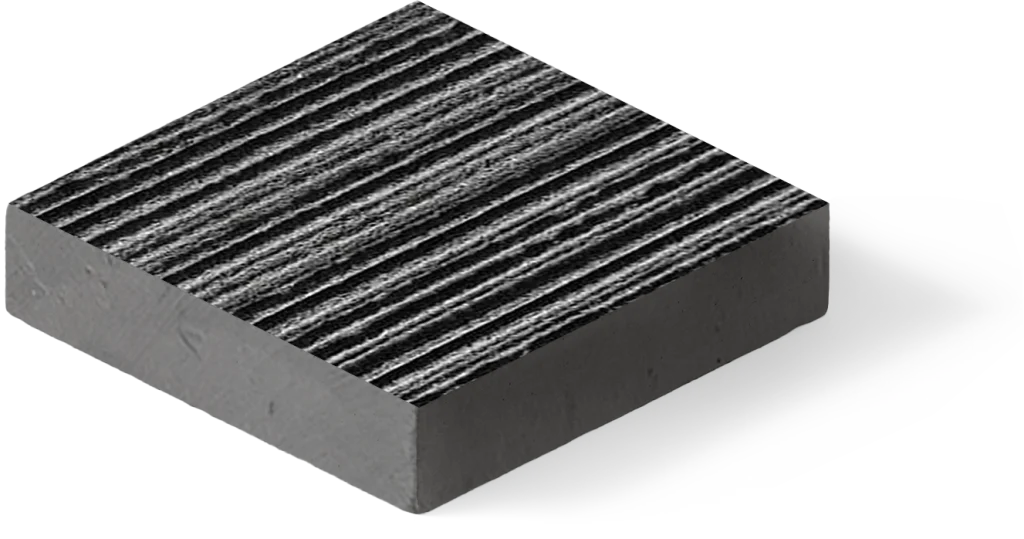

The flamed finish is a surface treatment in which a smooth stone surface is exposed to high-intensity flame. This rapid heating followed by sudden cooling causes the surface minerals to expand, burst, and flake, creating a rough and textured surface commonly used in architectural Stone Products. At karimi stone, this process is carefully controlled to achieve consistent texture and long-term performance.

This treatment is typically applied to strong and dense stones such as granite and hard marble. Flamed Stone Products from karimi stone are mainly used in outdoor applications, where the rough surface provides excellent slip resistance along with a natural, rugged appearance suited to exterior environments.

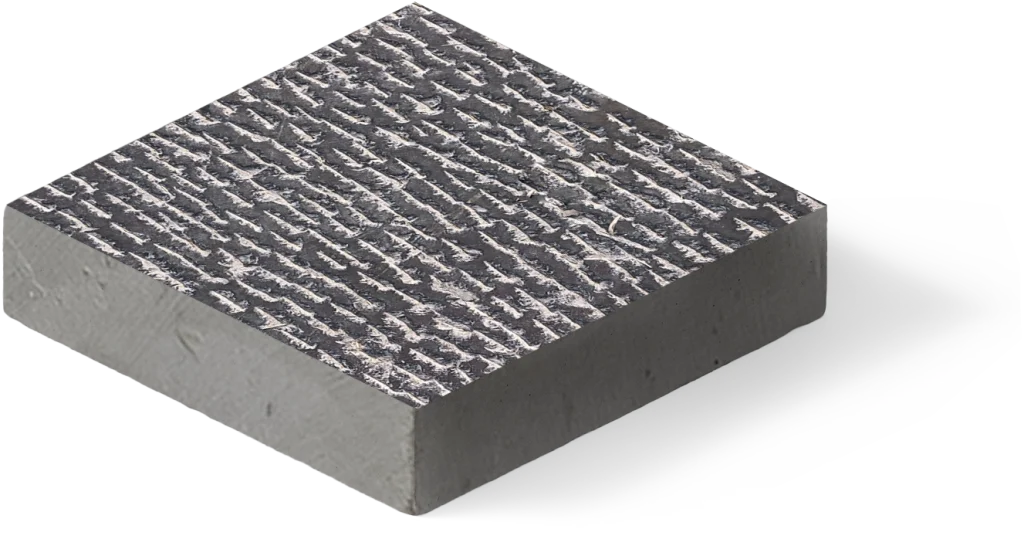

The Hand-hammered finish is a traditional stone surface treatment primarily practiced in Iran and performed entirely by hand. This technique is rarely found in other countries, where mechanical methods are typically used to achieve a similar texture known internationally as the bush-hammered finish. In artisanal Stone Products crafted by karimi stone, this traditional method preserves the authenticity and character of the stone.

During the Hand-hammered process, skilled craftsmen use specialized hammers with various head types to create fine, coarse, or uniform surface patterns. Because the work is done manually, this finish gives Stone Products from karimi stone a distinctive artistic quality and a natural appearance, making it one of the defining expressions of Iran’s stone craftsmanship.

In the cut-broken process, the stone surface is first grooved and then the grooved edges are broken either manually or mechanically. This method creates irregular and natural edges that add character to architectural Stone Products. At karimi stone, this process is carefully controlled to maintain consistency while preserving a natural look.

The resulting cut-broken Stone Products from karimi stone feature a decorative, rustic appearance, making them well suited for façade applications and design-oriented architectural projects.

In the polished finish, after the stone is calibrated, it enters the polishing line where the surface is processed using a minimum of eight and up to fourteen polishing heads. This method is widely applied in high-quality architectural Stone Products. At karimi stone, polishing parameters are carefully controlled to achieve consistent surface clarity and gloss.

The initial polishing heads remove calibration scratches and level the stone surface. Subsequent heads carry out pre-polishing and full polishing stages, while the final heads are dedicated to acid treatment and final gloss enhancement. The higher the number of polishing heads, the faster the processing speed and the higher the surface quality of the polished Stone Products produced by karimi stone.

Polished Stone Products from karimi stone are commonly used in building interiors, including floors, lobby walls, and other interior architectural areas where visual clarity and reflectivity are desired.

As the name suggests, raw stone refers to stone with no applied surface treatment and is supplied exactly as it is cut, retaining natural saw marks on the surface. This finish is commonly used in specific architectural Stone Products where a natural and unfinished appearance is desired. At karimi stone, raw stone is produced with precise cutting to ensure dimensional accuracy.

For improved usability, raw Stone Products from karimi stone are typically calibrated and, if required, lightly smoothed using a single polishing head. This optional step helps enhance handling and installation while preserving the stone’s natural character.

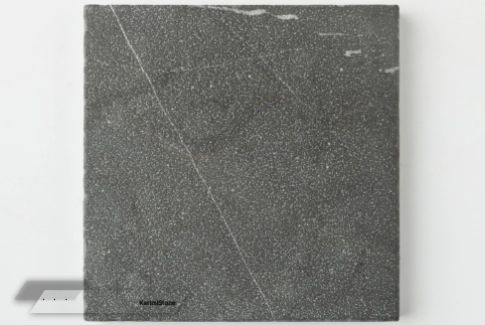

Pietra Grey Sandblasted & Brushed

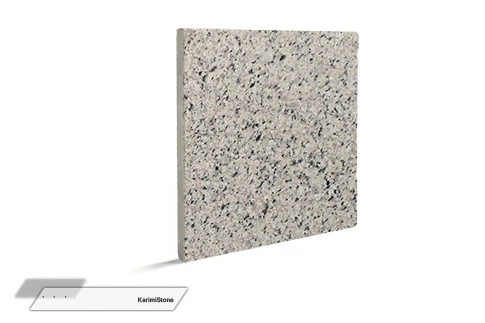

Peach Granite Polished

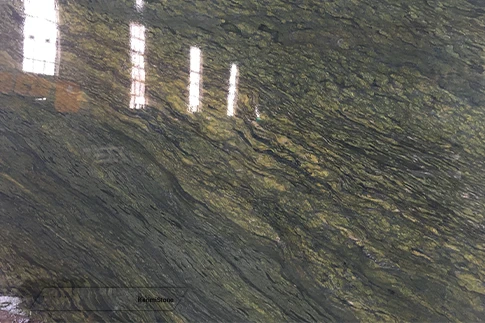

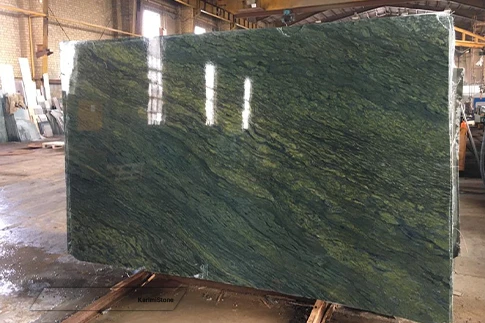

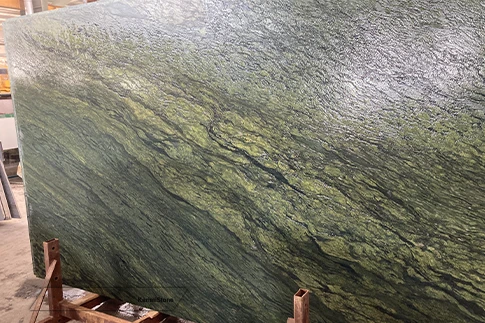

Green Granite Polished

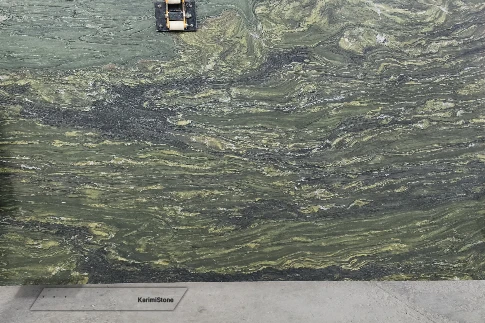

Green Granite Brushed

Red Granite Polished

Black Granite Sawn-cut

- Every Wednesday, there is an event.

Sep 17, 2025

Sep 24, 2025

Oct 1, 2025